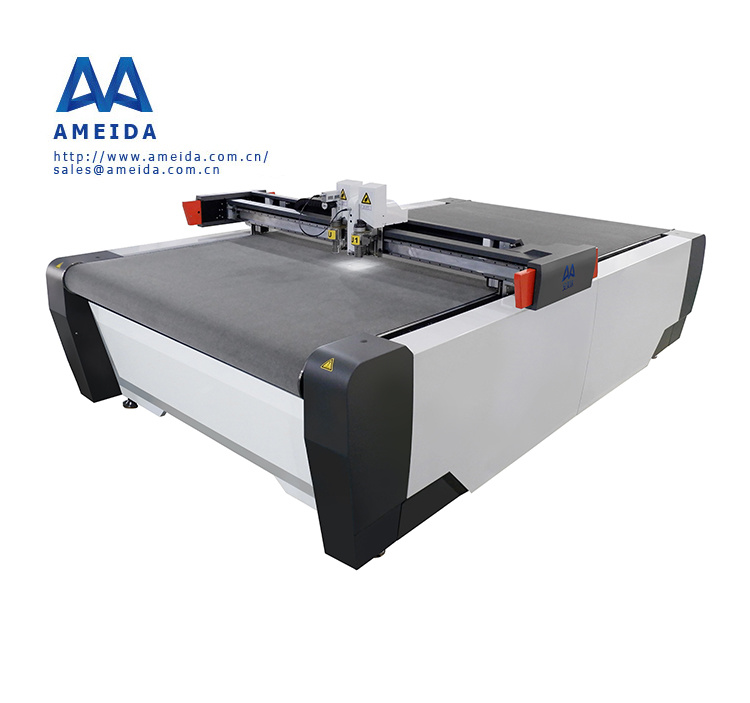

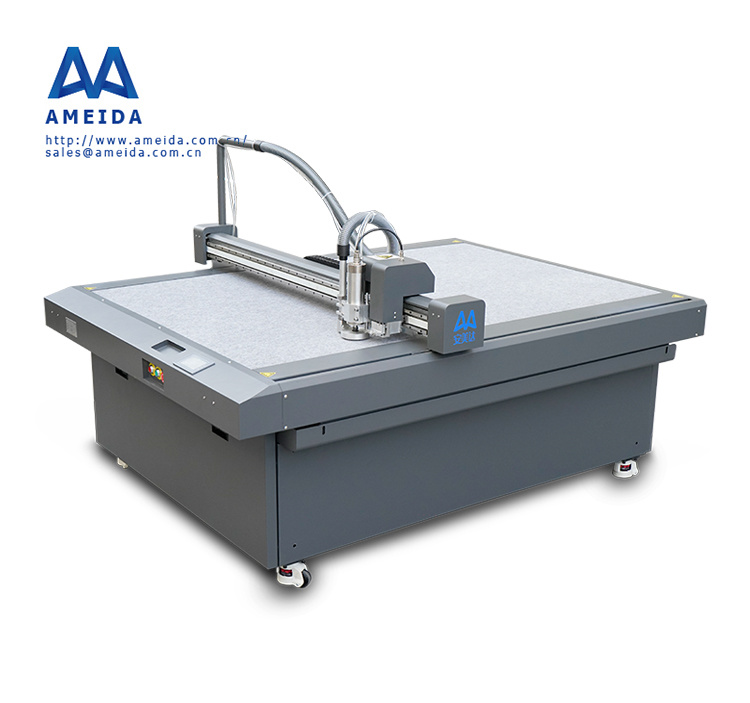

Fabric &Textile Digital Cutter – B3 Series

B3 Flatbed digital cutting system can realize through cutting, half cutting, creasing, milling, punching and nesting with high speed and high precision. With conveyor table, B3 can complete the material feeding and collecting with fast speed. It is quite suitable for sample making, short-run and mass production in Sign & Graphic, Packaging, Automotive, Gasket industries.

Keywor:

Classificar:

Fabric cutter

E-mail:

B3 Flatbed digital cutting system can realize through cutting, half cutting, creasing, milling, punching and nesting with high speed and high precision. With conveyor table, B3 can complete the material feeding and collecting with fast speed. It is quite suitable for sample making, short-run and mass production in Sign & Graphic, Packaging, Automotive, Gasket industries.

Advantage:

1. High speed Driven rotary tool, quick cutting single layer material, no need laminating.

2. With punch tool, pen, meet the cutting needs of a variety of fabrics in the apparel industry.

3. Automatic nesting system: fast and efficient layout, saving time and materials.

4. Conveyor table: continuous feeding, ultra-long cutting, cutting length is not limited by the length of the table.

5. Infrared sensing system: 360°surround security to ensure operator safety.

6. Imported servo motor/linear guide: Stable machine performance, long life and high precision.

Parameter:

|

Model |

B3-1013 |

B3-1815 |

B3-2516 |

B3-2518 |

|

Working Area(MM) |

1000*1300mm |

1800*1500mm |

2500*1600mm |

2500*1800mm |

|

Special Size |

Customizable |

|||

|

Safe Device |

Physical anti-collision mechanism + infrared induction anti-collision to ensure production safety |

|||

|

Standard Tool |

Driven rotary tool, Multi function punch tool, Cursor, Pen |

|||

|

Optional Tool |

Electric oscillating tool, Projector system, Camera |

|||

|

Cutting Material |

Knitted Fabric, Woven Fabric, Shearling, PU Leather, Oxford, Canvas, Sponge, Fake Leather, Cotton&Linen And Other Clothes/Luggage/Sofa/Mat/Carpet Material |

|||

|

Cutting Thickness |

≤5MM |

|||

|

Cutting Speed |

300~800mm/s |

|||

|

Cutting Precision |

≤0.1mm |

|||

|

Repeated Accuracy |

≤0.1mm |

|||

|

Fixing Method |

Vacuum suction |

|||

|

Interface |

Ethernet port |

|||

|

Driving System |

Intelligent digital control servo system |

|||

|

Command |

DXF, HPGL compatible format |

|||

|

Control Panel |

Multi-language LCD touch panel |

|||

|

Suction Power |

1.5KW~9KW(Variable frequency air pump is optional) |

|||

|

Power Supply |

AC220/380V 50~60Hz |

|||

|

Working Environment |

Temperature: -10° ~ 40° Humidity: 20%~80% |

|||

Application:

Machine Details:

Tool Suggest:

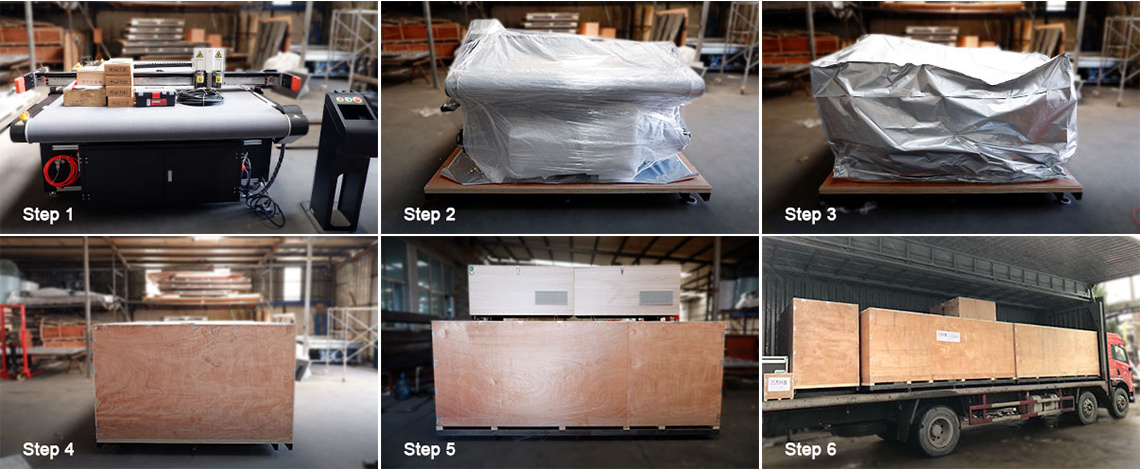

Packaging process

Previous

Next

Previous

无

Next

We sincerely looking forward to cooperating with you !

Add

No.188-1, Shanhai Road, Haishu district, Ningbo, China

Tel/ WhatsApp